Robot for Pallet Transportation (Skateboard)

Goal of the project

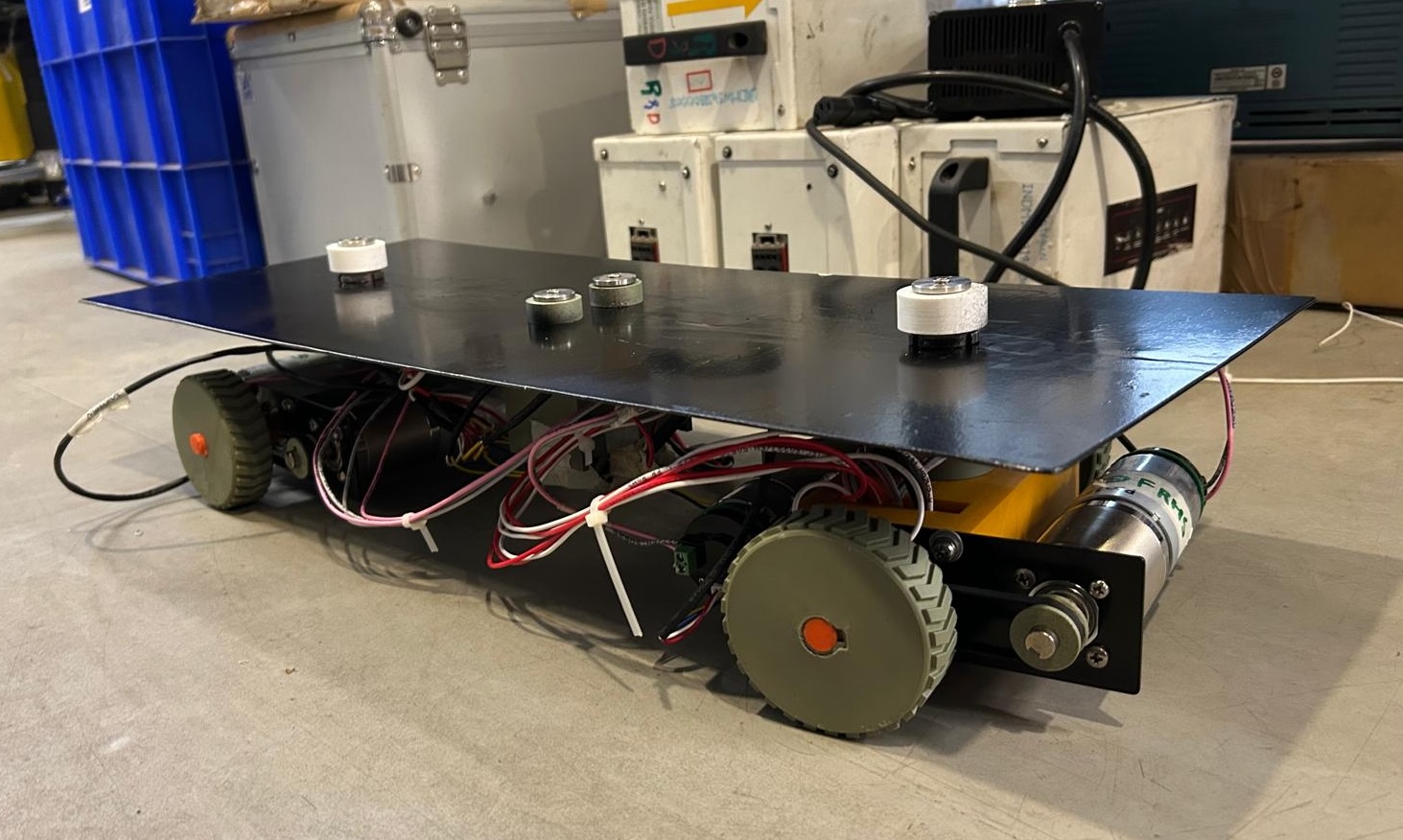

In the summer of 2025, during my internship at ATI Motors, I built a prototype of an intelligent fork for pallet transportation. “Skateboard” was the nickname given to the project.

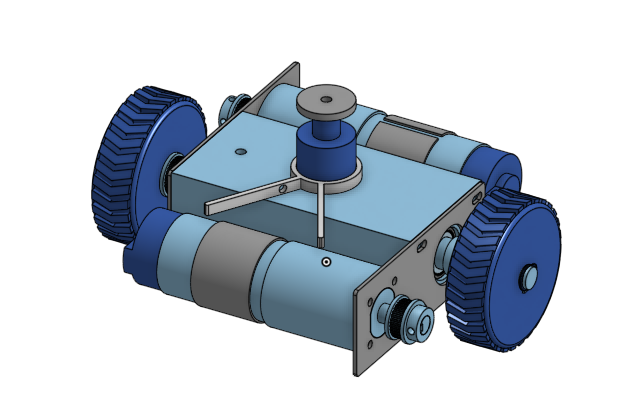

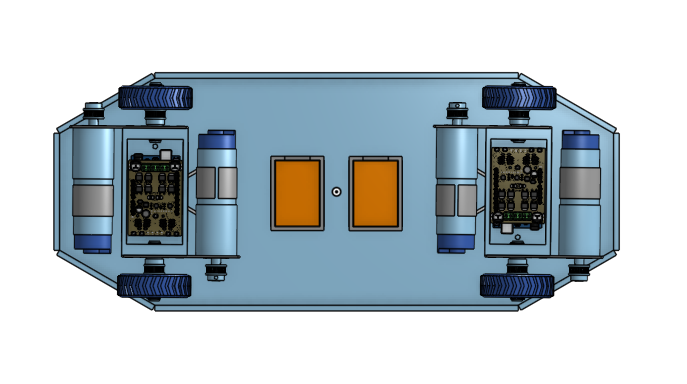

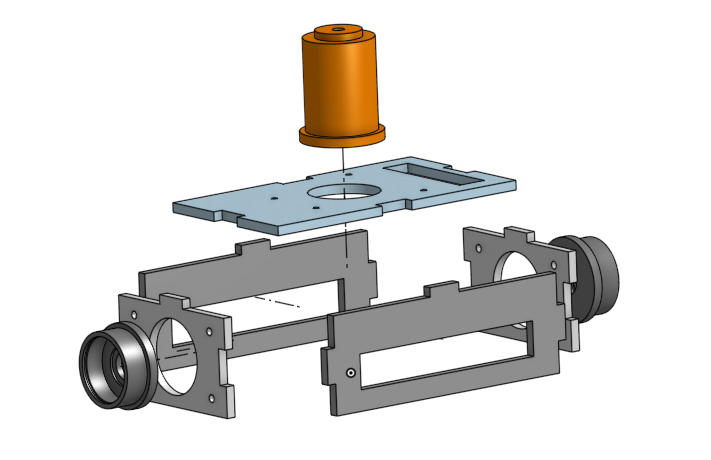

The skateboard’s key advantage over pallet movers and similar machines is its ability to move omnidirectionally and perform zero-radius turns. This increases positional accuracy and could potentially save time and space. It also uses an electronic differential rather than a mechanical one, which is more compact and precise.

Design Process

For this project, I used Onshape for CAD work, SimScale for FEA analysis, and the Arduino IDE for hardware tasks. Most parts were either 3D-printed, laser-cut, or machined.

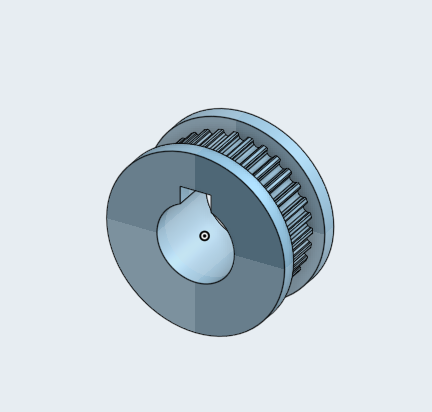

Before I began, some components such as the motors, encoders, pulleys, and microcontrollers had already been selected by the company. To fit the given constraints, I designed my own GT2 pulleys and other parts for the electronic differential unit.

Through this process, I learned how to model sheet metal parts in CAD and got many of my designs laser-cut and welded.

Electronics and Test Bench

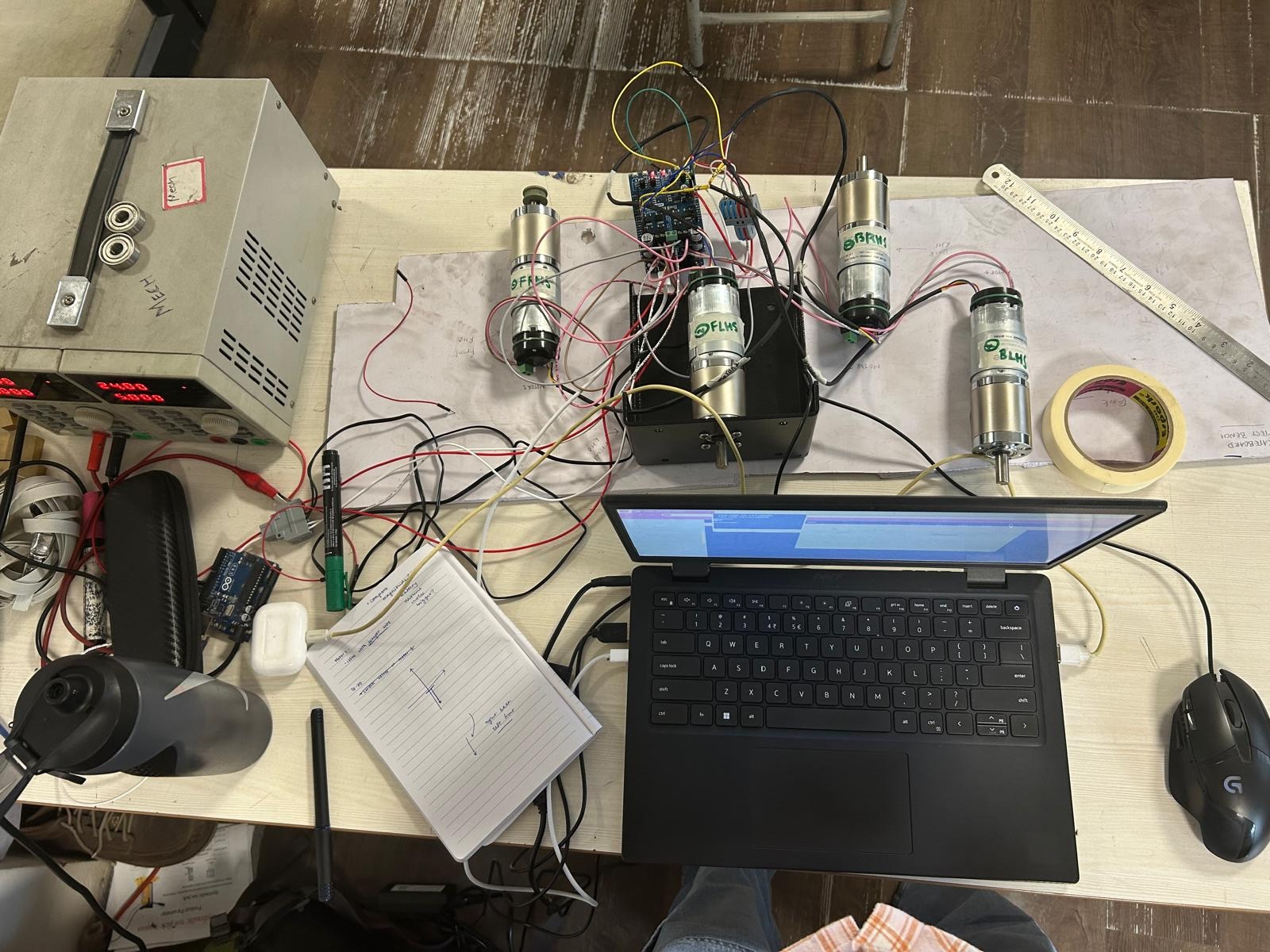

After designing the complete assembly and sending parts to be either manufactured or 3D-printed, I worked on the electronics.

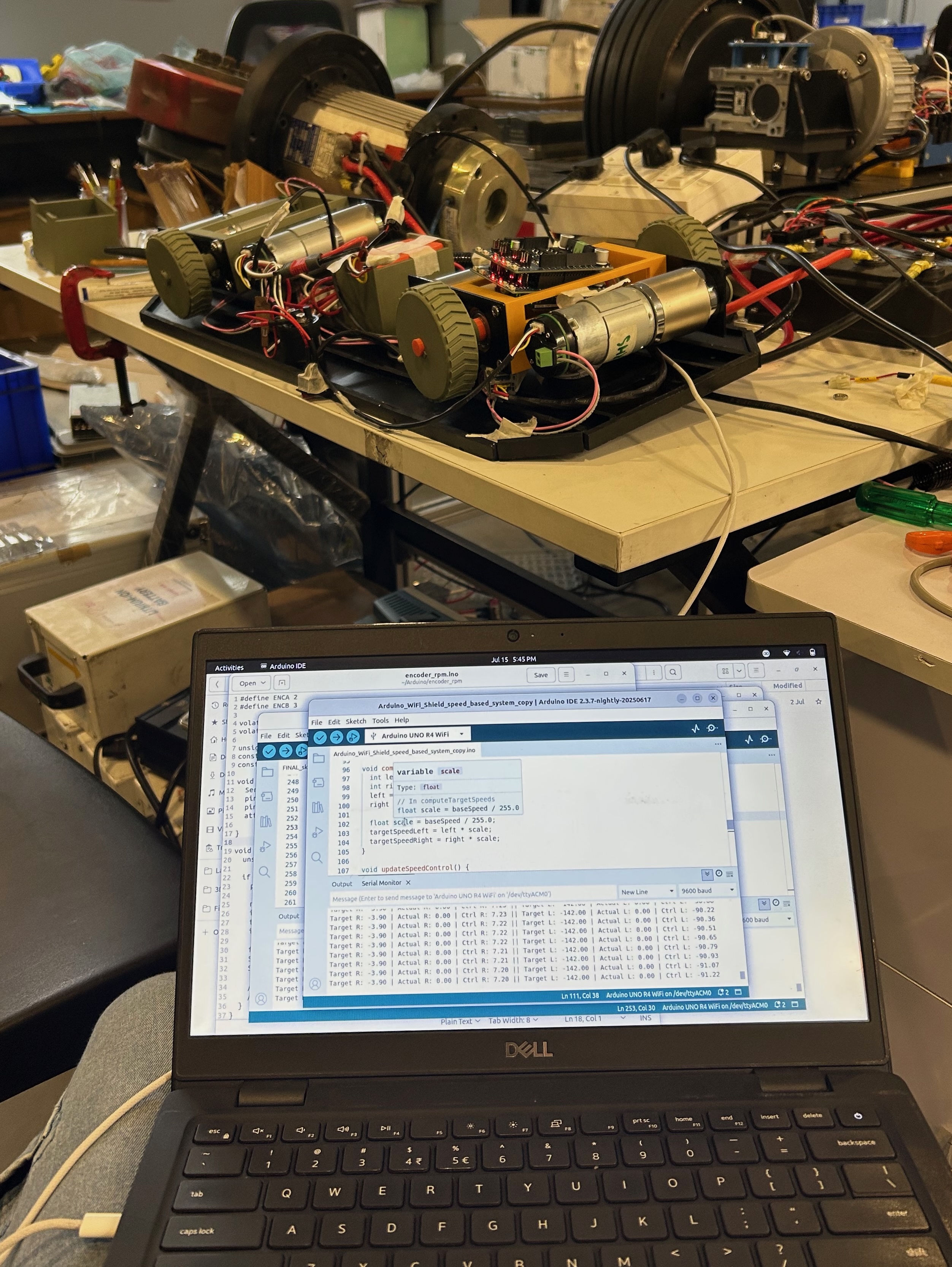

The circuit consisted of a stack of an Arduino and two motor driver shields that powered and controlled the four motors using data from quadrature encoders. I wrote a PID-based program that monitored the ticks and positions of the wheels’ rotations.

Then, I started exploring different methods for communicating with the microcontroller system. My options were:

- Blynk (an IoT platform)

- MQTT

- Wi-Fi communication over a Flask server

I chose the third option and ran a web server on my laptop to control the Arduino with an ESP32. To validate my code and setup, I created a test bench with the motors and all electronic components.

Assembly

I then moved on to assembling all the parts, which had been manufactured by then. During this process, I realized that the foamboard was too weak to hold the weight of the motors, so I cut and drilled holes into a piece of scrap metal instead.

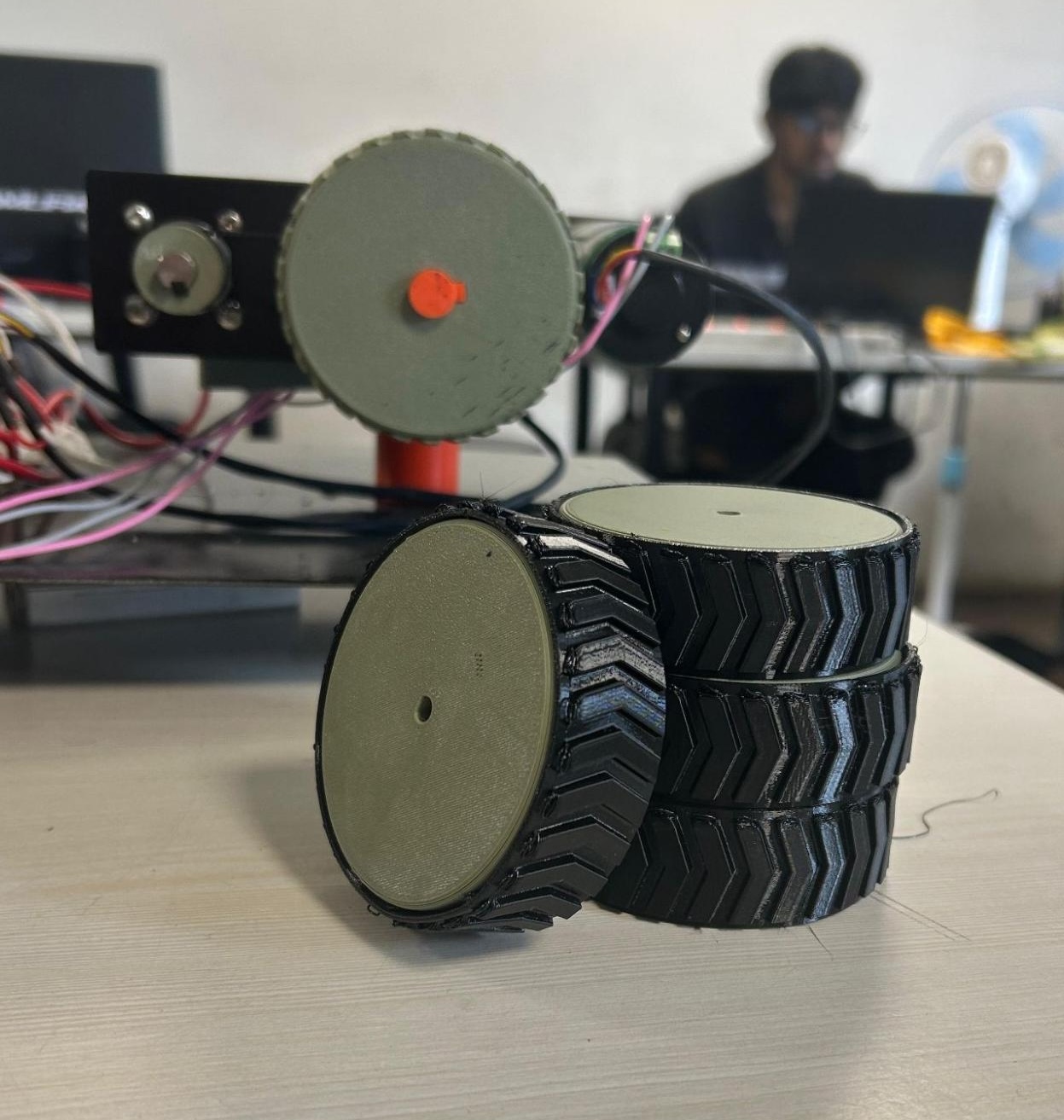

I faced some issues with the 3D-printed parts breaking, but after some changes and reprinting, I was able to run the prototype on the ground and test my code and other ideas.

With the design approved, I moved on to getting all parts manufactured in metal. This meant modifying some of the designs for better manufacturability.

This was the outcome of three months of work at ATI Motors, and the company plans to continue developing my work into an actual product. I truly enjoyed the learning process, and it was gratifying to see the final product come to life. I look forward to taking on more challenging and interesting projects like this!