Purdue ROV (Remotely Operated Underwater Vehicle)

This semester, I joined the Purdue ROV team. This student-led team builds an underwater robot that performs tasks to protect the ocean’s ecosystem. These tasks are stipulated by the MATE ROV competition, a yearly World Championship that we take part in over the summer.

This year, the competition is in Newfoundland & Labrador, Canada, and to go with the theme of the location, our robot should be able to handle low temperatures in an ice tank, high water velocities in a flume tank, and saltwater in an offshore engineering basin.

Project Introduction

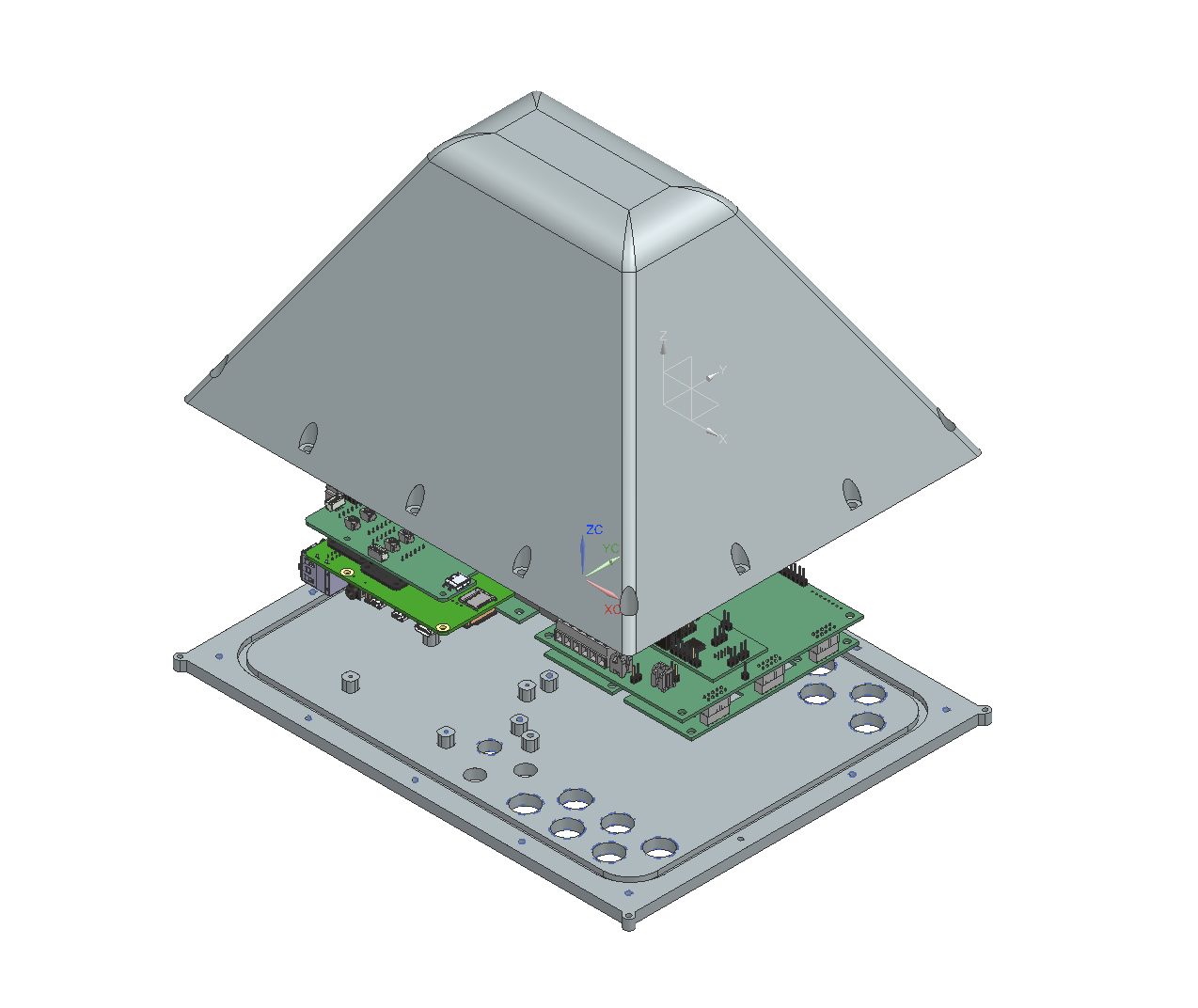

I am a part of the Mechanical team and am working on the electronics enclosure of the vehicle. This includes a carrier plate and a lid that together should be waterproof and handle water pressure at approximately 7.5 meters deep.

The lid prevents the electronics from contacting water and has all the team members’ names embossed onto it.

The plate has scaffolding to hold the electronic stack and holes for binders.

Carrier Plate

The carrier plate will be anodized aluminum with through holes to screw the lid onto it. It also has a slot for an O-ring.

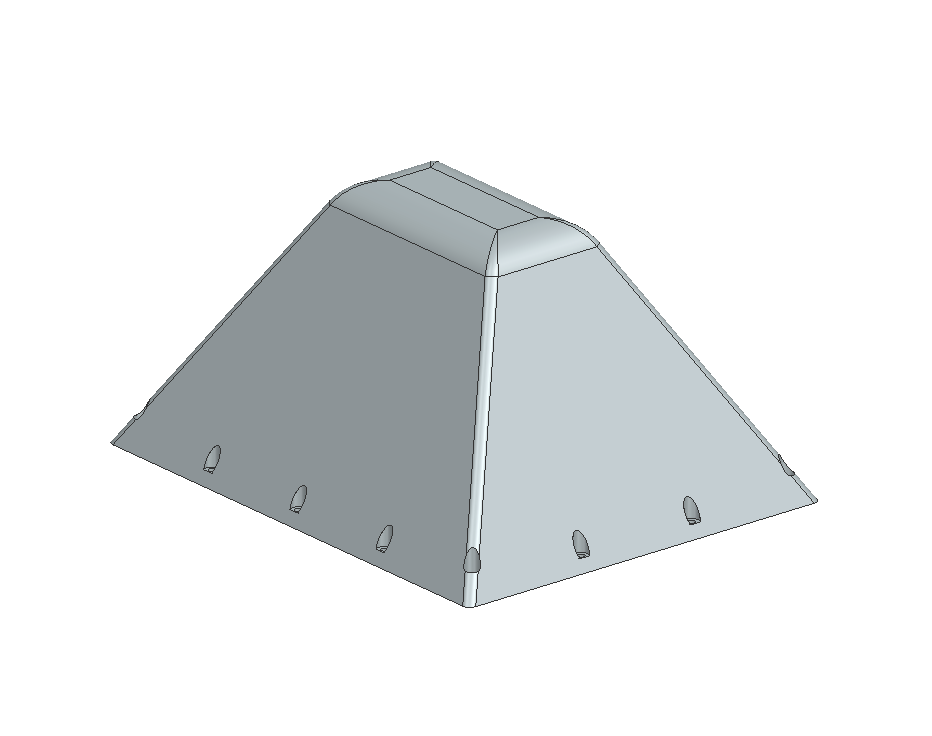

Enclosure Lid

The lid will be resin printed using Formlabs Clear Resin V5. This year, we transitioned from aluminum (used for the plate) to a clear resin design, which I have been leading. The new material makes the lid lighter, visually cleaner, and allows for easier leak detection.

Previous years also had the enclosure in a more box-like shape, but now I am still experimenting with different shapes to make it more hydrodynamic for the rougher conditions.